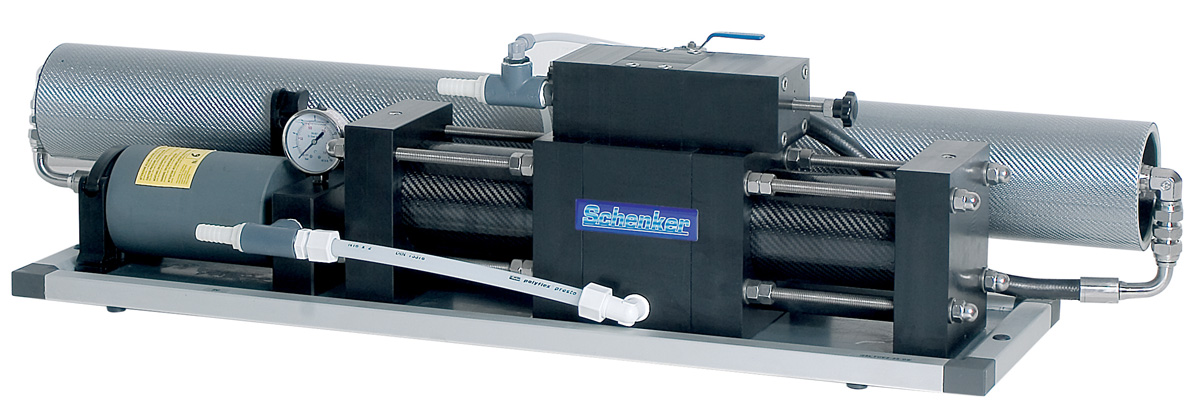

The Schenker Watermaker Smart 100 convinces with high-quality manufacturing, low energy consumption as well as with a sophisticated, compact, modular design.

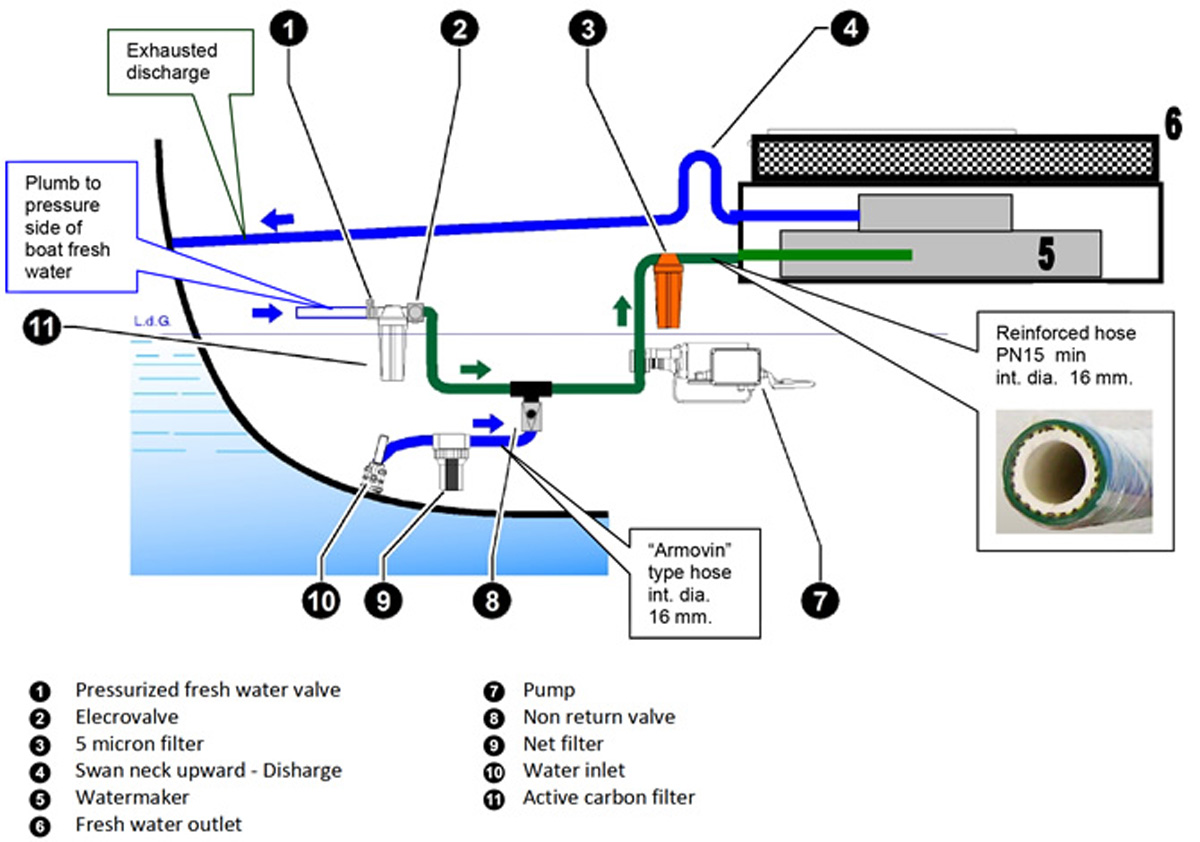

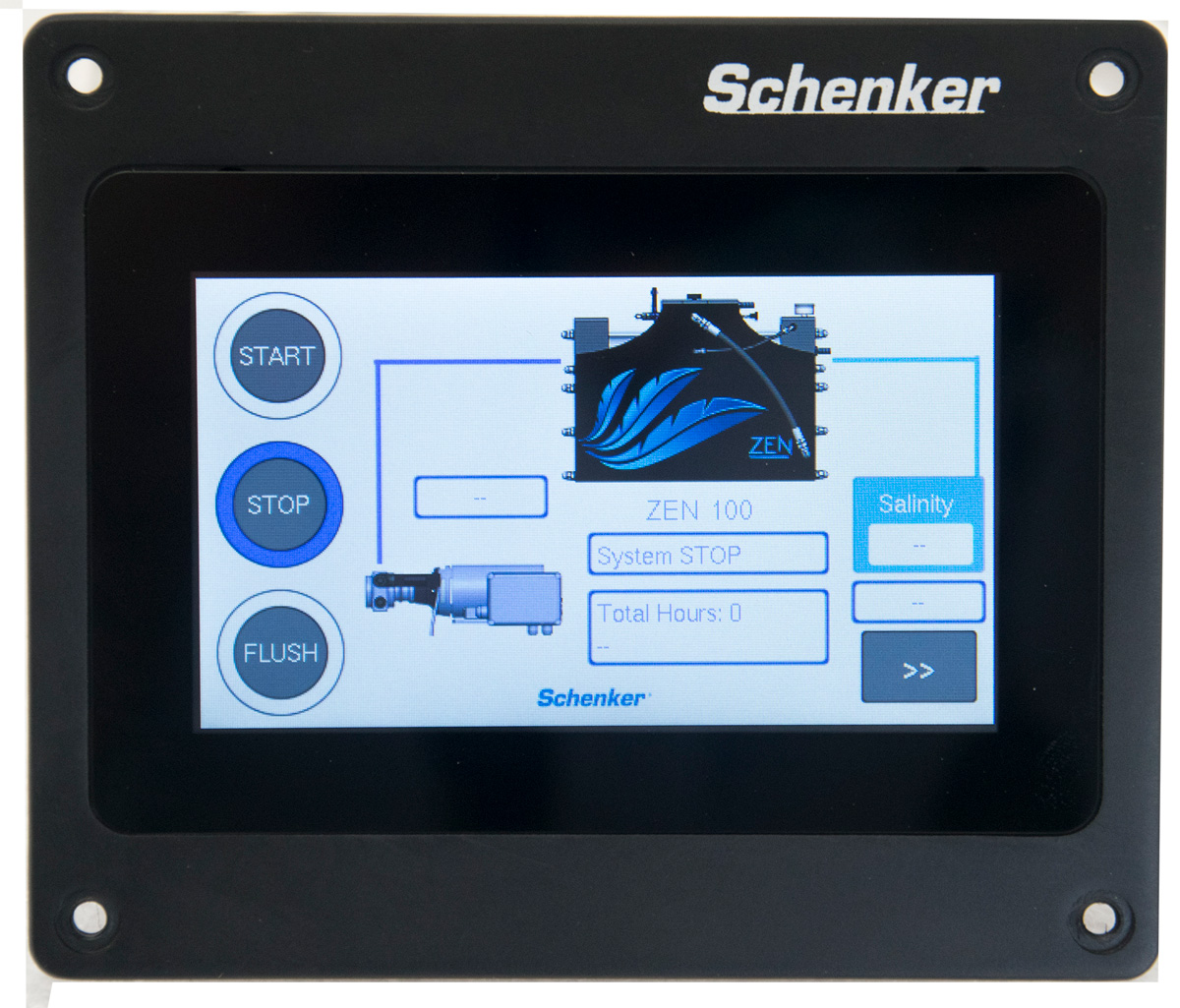

The desalination plant of the Smart product line consists of the watermaker unit (membrane and Energy Recovery System - ERS), the pump unit, the filter units and the control panel (Basic, Digital or Touch). The ERS is located along the membrane. Both elements of the watermaker unit are thus easily accessible for maintenance and inspection. Thanks to its open design, the Smart 100 is ideal for sailors who value easy maintenance options and prefer space-saving installation thanks to its modular design.

The Smart 100 watermaker produces 100 liters of fresh water per hour (26.4 gallons per hour) via reverse osmosis. Thanks to Schenker's patented Energy Recovery System (ERS), energy consumption is very low at 400 watts per hour (approx. 4 watts per liter / approx. 15.2 watts per gallon of water produced). The power consumption is up to 80% lower compared to conventional desalination plants. This makes the unit particularly suitable for self-sufficient water production. The watermaker can be connected directly to the on-board power supply (12 volts / 24 volts) or to alternating current (AC, 230 volts).

The processing of high-quality materials for all components and the well thought-out design make the Smart 100 not only quiet running and low on vibration, but also keep the device absolutely corrosion-free and ensure its long life.

Many recreational and circumnavigational sailors rely on the reliable Schenker products with low power consumption. In combination with alternative energy sources such as solar and wind power, they enable an independent lifestyle on the water.

|

|

|

|

|

|

|

The offered package of the Schenker Watermaker Smart 100 includes:

- Main unit with membranes and Energy Recovery System (ERS)

- Pump unit

- 1x Activ Carbon filter with cartridge and electro valve

- 1x 5 Micron filter with housing and accumulator

- Net filter

- Non-return valve with T-piece

- Remote panel Basic, Digital or Touch (see product options) with connecting cable (10 m)

- Filter wrench

- Fresh water hose for connection to fresh water tank (6×8 mm, 5 m)

- Installation kit: brackets, bolts, etc.

- Manual

The package content of Schenker products is very extensive. Only additional components are required for installation, which depend on the installation location on the yacht and the individual conditions on board.

Hoses and connections:

Please also consult the manual (chapter 4.4).

- Low pressure water hose for connection seawater inlet to pump unit: PVC suction hose (reinforced) with steel spiral, PN 6, 20 mm internal hose diameter, individual length according to conditions on board.

- Low pressure water hose for discharge of residual water: PVC suction hose (reinforced) with steel spiral, PN 6, 16 mm internal hose diameter, individual length according to conditions on board.

- Medium pressure water hose: Rubber reinforced hose, min. PN 16, 20 mm internal hose diameter, individual length depending on conditions on board.

- Hose clamps: 25 - 40 mm, depending on the outer diameter of the hoses (we recommend installing 2 hose clamps per connection, in total approx. 34 for the entire installation).

- Teflon Sealing Tape (PTFE).

Electrical connections:

Please consult chapter 4.5 in the manual. In this chapter, the electrical connections are explained very well with drawings and photos and the correspondingly required cables can be determined. If you have any questions, please do not hesitate to contact us.

Optional:

The following components may be required additionally, depending on the conditions on board:

- Through-hull fitting for seawater supply (min. ¾" thread): Very often existing through-hull fittings can be used (connection via T-piece into existing hose). In chapter 4.3, you find the requirements for the existing through-hull fittings for the supply of seawater.

- Through-hull fitting for discharge of residual water (min. ½" thread): If an existing drain is used, it is important that no dirty water can flow back to the watermaker unit (see chapter 4.3).

- Gooseneck: The integration of a gooseneck in the discharge of the residual water is necessary when the through-hull fitting of the discharge is lower than the watermaker unit (membranes and ERS).

- T-piece connector: min. 16 mm internal diameter (when using existing seawater and wastewater piping).

- Fresh water pump: The capacity of the usually already existing fresh water pump (supply of fresh water from the water tank to wet cells and galley) must be at least 20 liters per minute at 1 bar flow rate.

Consulting on installation by MAR nautic:

To carry out the installation planning with the corresponding required accessories, please consult the manual. We will be happy to assist you in planning the installation as well as in selecting the necessary installation accessories.

Please also consult chapter 6 in the manual. Please distinguish between routine maintenance, cleaning and preservation.

Routine maintenance:

Some routine maintenance operations require the replacement of the following products:

- 5 Micron filter (10 in): in case of normal use of the watermaker, replace after 100 to 120 working hours (depending on the quality of the water, we recommend changing the filter more frequently).

- Activ Carbon filter (10 in): to be replaced once a year.

- Membranes (4 in x 40 in): to be eplaced every 6 to 7 years.

Cleaning and preservation:

The Cleaning Products SC1 and SC2 are used as follows:

- The Cleaning Product SC1 (acid-based) is used for resting periods of two to three months or more (preservation of the system) or in the case of dirty membranes (e.g. recognizable by too high working pressure). This product removes inorganic elements.

- The Cleaning Product SC2 (alkaline) is used in case of bad smell of the produced water. This product removes organic elements (including bacteria) in the system.

Manual Schenker Smart 100 Digital 12/24V - English

Manual Schenker Smart 100 Digital 230V - English

Manual Schenker 100 Touch 12/24V - English

Manual Schenker Smart 100 Basic 12/24V - Italiano

Manual Schenker Digital100 Digital 12/24V - Italiano

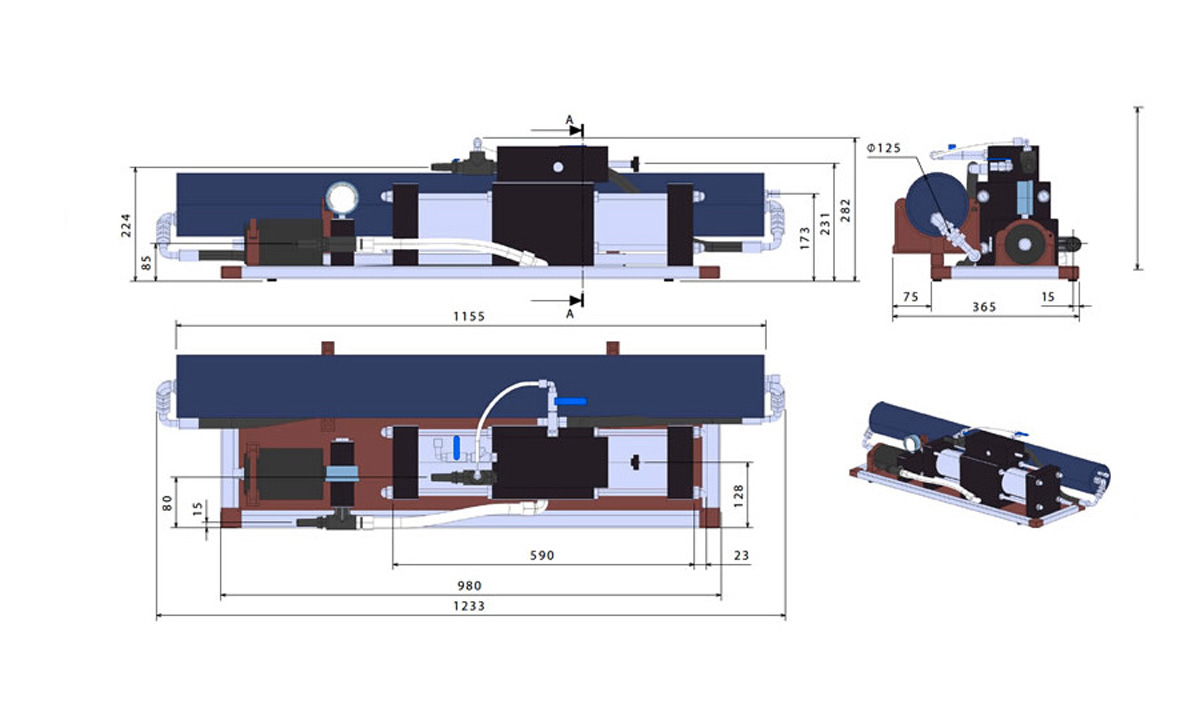

Technical drawing Schenker Smart 100 - watermaker unit

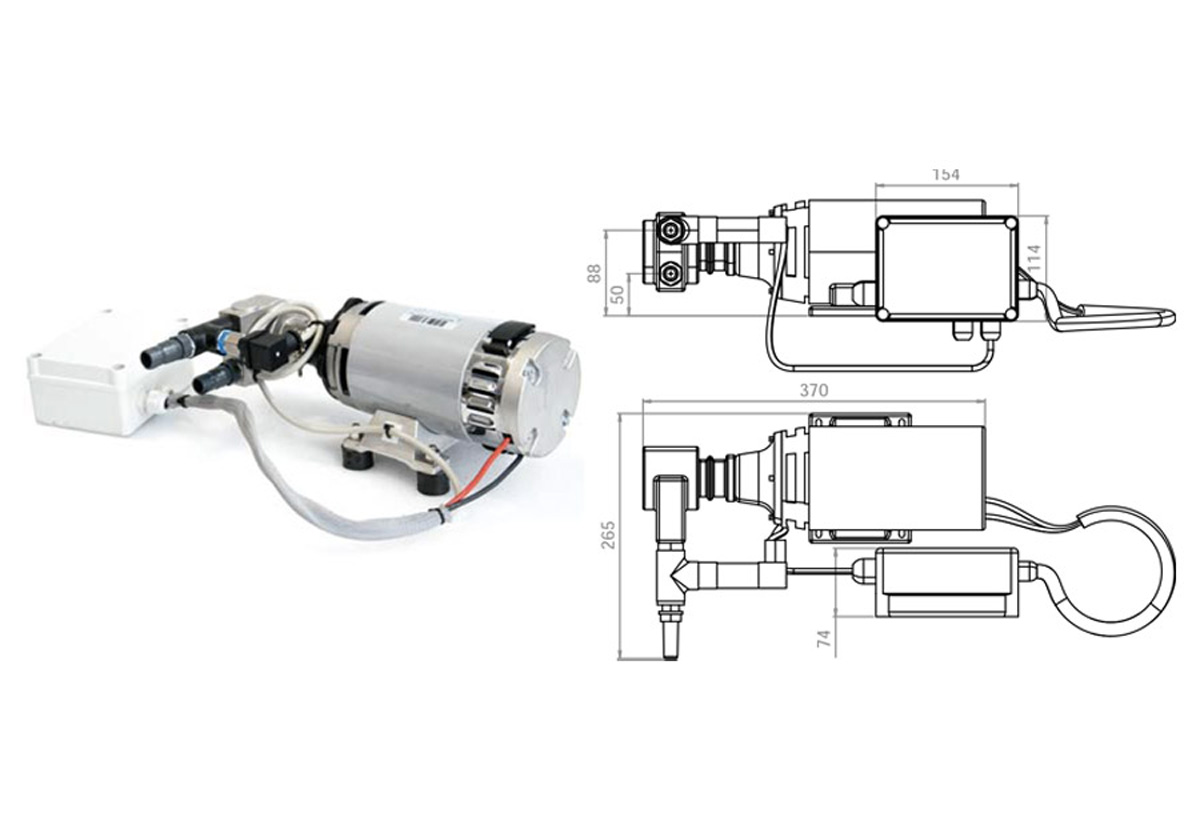

Tecnical drawing Schenker Smart 100 - pump